Philippe Alibert, founder of the companies BEST and LOuss, was among the few who had faith on the LED technology in the early 2000s. He implemented an ambitious Research and Development program with the aim to propose elegant and efficient LED lighting devices.

This strategic choice is in part related to the interest that represents the LED technology for the environmental protection.

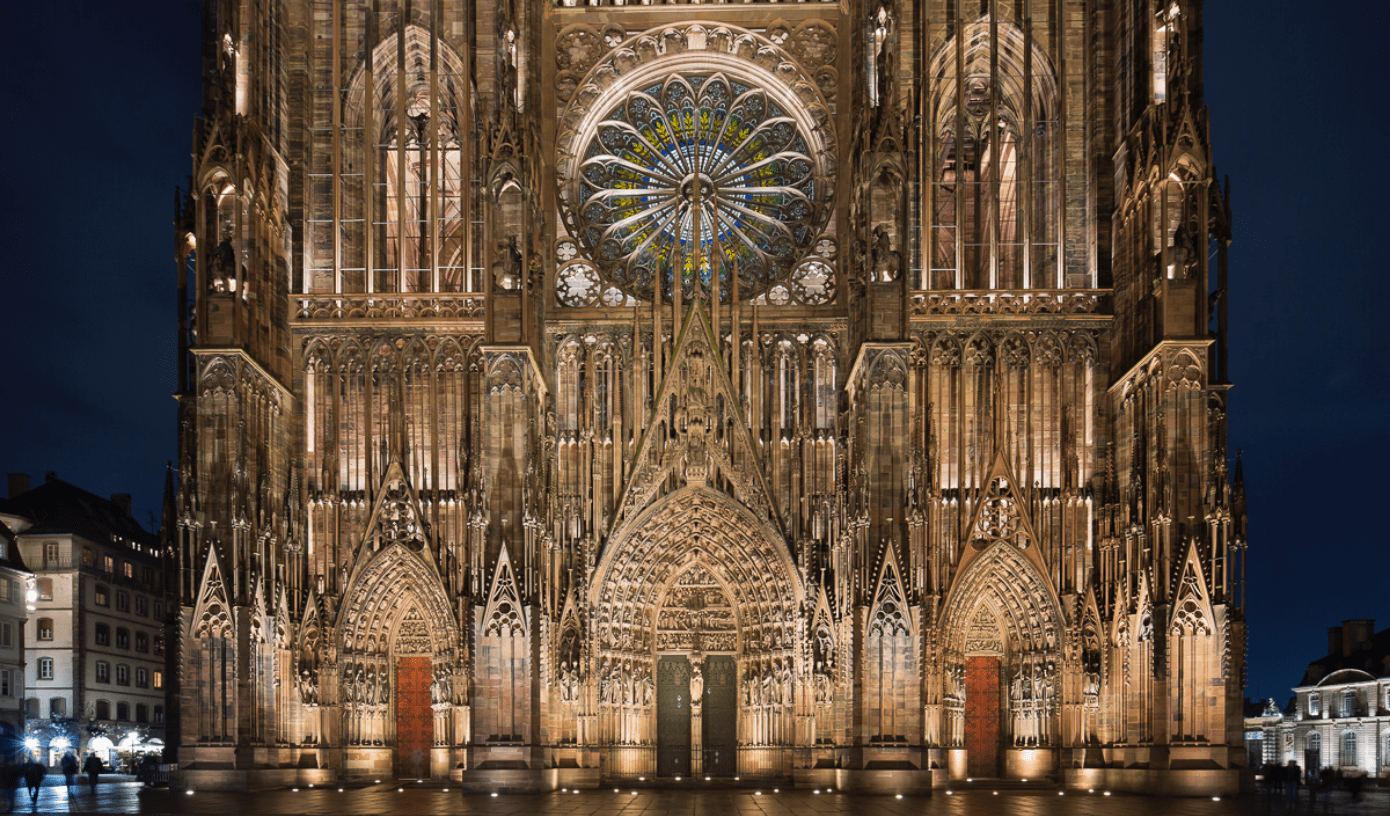

LOuss, emotion

lighting